Niobium is a glossy, white metal that ordinarily shapes a film on its surface when presented to air, turning shades of blue, green, or yellow. It has a wide scope of employment from use in hypoallergenic adornments to stream motors to superconducting magnets.

- Nuclear (number of protons in the core): 41

- Nuclear image (on the occasional table of components): Nb

- Nuclear weight (normal mass of the iota): 92.906

- Thickness: 8.57 grams per cubic centimeter

- The stage at room temperature: Solid

- Dissolving point: 4,491 degrees Fahrenheit (2,477 degrees Celsius)

- Breaking point: 8,571 degrees F (4,744 degrees C)

- Number of isotopes (particles of a similar component with an alternate number of neutrons): 35

- Most basic isotopes: Nb-93 (100% common plenitude)

Properties:

Modern uses for niobium stretch as far back as the mid-1900s, and more advantages are being found and applied for this important component over the long haul.

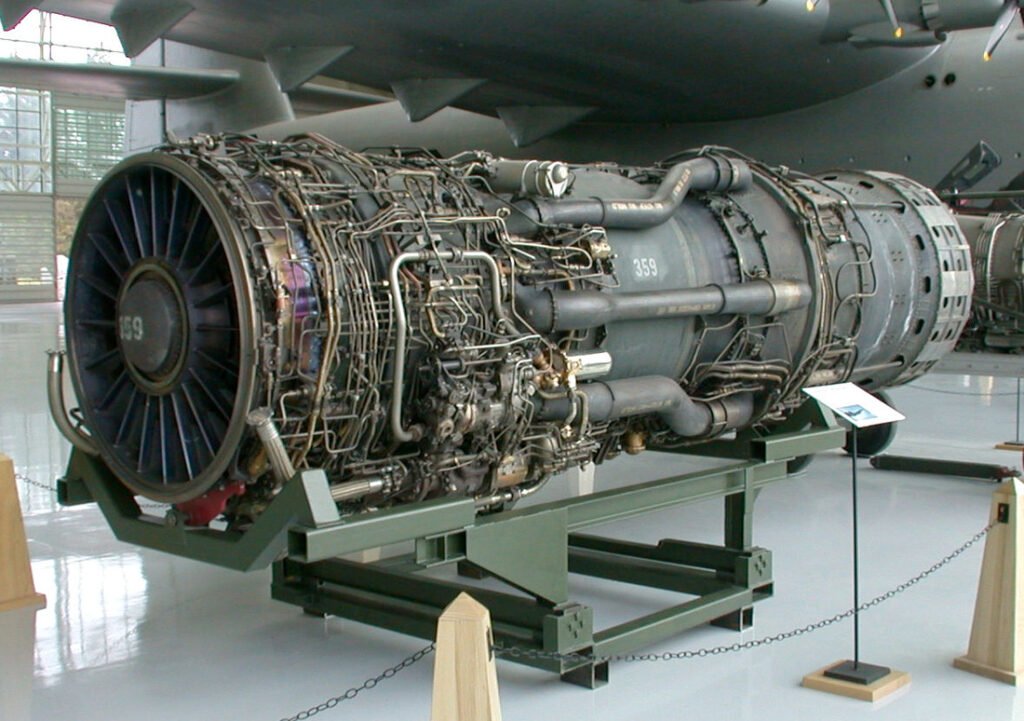

Niobium is most generally used to make amalgams. Indeed, even with as meager as 0.01% niobium, the quality of steel is particularly improved. These combinations are regularly found in oil and gas offices and pipelines. Niobium superalloys, for example, nickel niobium, have an evident capacity to look after security, making them exceptionally attractive in rockets and fly motors just as land-based turbines in power plants.

Niobium titanium composites are superconductive under certain low-temperature ranges. These compounds are utilized to make superconducting magnets utilized in MRI scanners.

History:

Niobium has a tangled history. John Winthrop found a mineral in Massachusetts in 1734 and sent it to England. The mineral sat in the British Museum assortment for quite a long time until it was investigated in 1801 by Charles Hatchett. He found another component in the mineral and named it columbium after Columbia, the graceful name for America. In 1809, William Hyde Wollaston, an English physicist contrasted columbite and another mineral, tantalite, and pronounced that columbium was really the component tantalum. The two components are fundamentally the same, are constantly discovered together, and are hard to seclude.

In 1844, Heinrich Rose, working with tests of columbite and tantalite, delivered two new discrete, yet fundamentally the same acids, which he named niobic corrosive and peloric corrosive. He renamed the component niobium. After twenty years, Swiss scientific expert Jean Charles Galissard de Marignac disconnected metallic niobium by warming the chloride in a hydrogen-air.

The component was called columbium (image Cb) in the United States for around 100 years, while it was called niobium in Europe. In 1949, the International Union of Pure and Applied Chemistry traded off and authoritatively embraced niobium as the component’s name, in yielding to European use. Thus, the association acknowledged tungsten instead of wolfram as the name for Element No. 74 (which actually conveys the image W), in concession to American use. Numerous metallurgists and metal social orders, notwithstanding, still allude to niobium as columbium.

FACTS:

- Niobium is named for the Greek goddess of tears, Niobe, who was the little girl of lord Tantalus, as indicated by the Royal Society of Chemistry, because of the component’s likenesses to tantalum (named for the ruler).

- Niobium and tantalum are almost consistently discovered together in nature, as per the U.S. Geographical Survey (USGS).

- The International Union of Pure and Applied Chemistry authoritatively embraced the name niobium in 1950, as per Los Alamos National Laboratory. Be that as it may, the component’s other name, columbium, is still broadly utilized today.

- As per the USGS, essentially all niobium is mined in Brazil and Canada. The assessed measure of niobium in the Earth’s outside layer is thought to keep going for the following five centuries.

- As per Lenntech, while a few mixes of niobium residue can cause eye and skin aggravation, there are no known instances of any genuine impacts of working with niobium. There are likewise no known natural impacts of niobium.

- As indicated by USGS, almost 80% of niobium is utilized in the steel business to make high-quality low-composite preparations. The utilization of niobium in these combinations builds the prepared mechanical and high-temperature quality, sturdiness, and erosion obstruction.

- Different employments of niobium, as indicated by Chemicool, incorporate pipeline development, superalloys for heat-safe gear including plane motors, and in gems.

- Niobium, tungsten, molybdenum, tantalum, and rhenium are known as the five hard-headed metals, as per Chemicool. These metals all have high protection from the warmth and wear.

Current research:

Niobium, because of its assortment of properties, is utilized in a few zones of examination. One such examination is in making magnets. One of the most grounded superconducting magnets on the planet utilizes niobium composite wires, for example, niobium-tin and niobium-titanium, as per National High Magnetic Field Laboratory. The 2.3-ton magnet is made of loops of three kinds of wire, two with niobium, and arrives at field qualities of 32 teslas (the quality of Earth’s attractive field on the outside of the planet goes from 30 to a little more than 60 microteslas or 30×10-6 to 60×10-6 teslas).

One such use for a superconducting magnet is in attractive reverberation imaging (MRI) or spectroscopy (MRS), as indicated by a 2018 patent. The superconducting magnet utilizes niobium-titanium wire curls to make an underlying attractive field and extra loops of niobium-tin wire to make an auxiliary attractive field. The two fields join to make a more grounded attractive field that the more customary niobium-titanium superconducting magnet.

WhatsApp Us

WhatsApp Us