Misfortunes because of corrosion have been foreseen to be of the request for 2 – 5% of the GNP of any nation. In India, the misfortunes because of the effect of erosion have been evaluated generally of 25,000 crores rupees for each year, as per NACE, India. A large number of these misfortunes are because of the consumption of iron and stainless steel, albeit numerous different metals may erode too. Pitting is a typical type of consumption which, on the off chance that it happens all through the outside of metal, is likewise named as uniform erosion and which in the end causes basic shortcoming and crumbling of the metal.

Steel is viewed as stainless steel when no base substance is indicated or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or some other component to be added to get an ideal alloying impact.

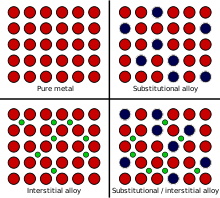

Metals represent around 66% of the considerable number of components and about 25% of the mass of the Earth. These are for the most part around us as metallic compounds which are utilized due to their different properties and qualities, for example, quality, malleability, strength, corrosion opposition, heat obstruction, thermal expansion, heat and electrical conductivity. The quality of metals is that their molecules are held together by solid holding powers.

Substitute to superalloys

Superalloys shows a few key qualities:

- fantastic mechanical quality,

- protection from warm wet blanket mishappening,

- great surface security,

- protection from consumption or oxidation in contrast with carbon steel.

Stainless steels demonstrate a few Alloy Steel Properties similar to superalloys and along these lines, in some basic applications where extreme consumption and high temperatures are of significant concern with the carbon steel, go about as a less expensive arrangement in subbing superalloys. Extraordinary evaluations of stainless steel have improved erosion opposition and high-temperature oxidation obstruction and quality contrasted with standard grades like 304 and 316.

Among the many contextual analyses exhibiting the estimation of these exceptional evaluations is Flue Gas Desulphurization (FGD) frameworks. The new outflows standards for coal-terminated force plants in regards to Sox and Nox, are sufficiently tough to command the force plants to be furnished with a FGD framework. While FGD is basically a straightforward procedure working under generally gentle conditions in correlation with other concoction forms in industry, various materials issues have been experienced.

The improvement of a wallpaper sheet fixing of stainless steel with super thin around 1.6 mm-2.0mm nickel-containing super-compounds is critical in this regard. A significant segment is the scrubber, which is for the most part exposed to a serious chloride condition. Be that as it may, with a two-circle framework, the 50,000-60,000 ppm chloride condition can be limited to the extinguish territory of the scrubber.

The staying scrubber regions with chloride substance in the couple of thousand ppm reaches will experience less destructive conditions and may not require exceptionally costly superalloys and too duplex tempered steel: rather UNS S32750 could be a less expensive arrangement. Cost-wise, tempered steel is multiple times less expensive than the essential evaluations of superalloys on a for each kilogram premise.

It can, in this way, be reasoned that relying on seriousness level for the moderate working conditions where carbon steel is second rate and super-amalgams could be substantially more prevalent, tempered steel could be the most fitting and conservative material.

WhatsApp Us

WhatsApp Us